https://www.pv-magazine.com/2022/04/07/renewable-offshore-floating-hydrogen-production/

Renewable offshore floating hydrogen production

Image: University College Cork, Renewable and Sustainable Energy Review, Creative Commons License CC BY 4.0

ClassNK, a Japanese ship classification society, has issued an approval in principle (AiP) for a floating offshore hydrogen plant that the Japan Offshore Design and Engineering Platform Technology and Engineering Research Association (J-DeEP) is developing off the coast of Scotland.

The hydrogen platform will be driven by surplus power generated by wind turbines. It will combine a seawater desalination system and a system to extract hydrogen from water through electrolysis. The project is being developed in partnership with the international arm of the Scottish government and Scottish Development International, which has helped J-DeEP to conduct the feasibility study.

“ClassNK conducted a safety evaluation on J-DeEP’s design of the plant in line with its rules and guidelines,” the organization said in a statement. “Upon confirming that the design complied with the relevant requirements, ClassNK has issued AiP.”

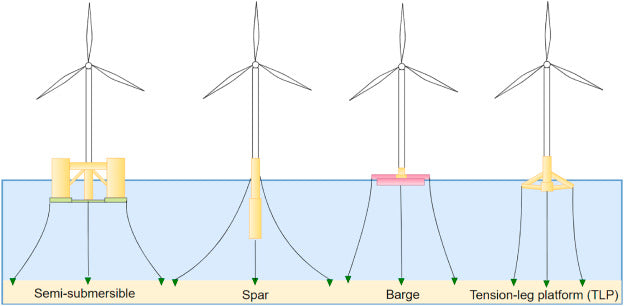

According to a recent study from the University College Cork in Ireland, the coupling of high-capacity floating offshore wind with green hydrogen production could be an important opportunity to further decarbonize the energy sector. The scientists have presented three project typologies based on variables such as electrolyzer technologies, floating wind platforms, and energy transmission. The typologies include offshore systems based on centralized onshore electrolysis, decentralized offshore electrolysis, and centralized offshore electrolysis.

“The energy transmission vector was the key feature of the three typologies discussed with emphasis on the major components of the systems, to limit the complexity of the paper while highlighting more detailed topics for future analysis,” the scientists said.

Popular content

They have found that the centralized system design is less complex than its decentralized counterparts, as it offers more cost-effective options for some components.

“For example, the ongoing development work in scale up of large size cost-effective electrolyzers may lead to cheaper hydrogen. On the other hand, the challenge to the centralized system is in the event of a failure, hydrogen production would cease for the whole farm,” they explained. “The centralized offshore system also has additional capex of a floating vessel accommodating the electrolysis facility.”

They explained their approach in “Dedicated large-scale floating offshore wind to hydrogen: Assessing design variables in proposed typologies,” which was recently published in Renewable and Sustainable Energy Review.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.