At the end of each year, safety issues become an important window period for testing photovoltaic power stations. With heavy snow, low temperature, cold climate, dry irradiation and so on, it is necessary to pay more attention to photovoltaic power stations to make them work stably in order to bring sustainable benefits.

Which links have hidden dangers? What factors lead to the loss of power generation? How to avoid it? Let's sort it out today.

Cable and fire prevention is very important

Fire prevention is the first priority for any engineering project. The power load of photovoltaic power station depends on AC cable. Generally speaking, the fire hazard of household power stations is small. The capacity of such power stations is generally between 20kW and 40kW. Although the voltage incorporated into the power grid may fluctuate, the overall current is not large. For example, the maximum output current of 40kW is about 66A. The probability of fire caused by the power station itself is very small. For large-scale photovoltaic power station system, the output current is relatively large, for example, the output current of a sub-array of 2.5 MW is more than 3000 A, and the inverter used is also relatively large. Before connecting to the box transformer, there are generally sub-bus cabinets. Cable is recommended to use flame retardant copper core cable. During the operation of the power station, the cables should be checked every six months to ensure good conductivity and safety. In winter, the outdoor temperature is low and in some areas it reaches tens of degrees below zero. Although the cable may be insulated during laying, the outer layer of the cable may be damaged after repeated temperature rise and fall. If found, it should be replaced in time.

Check DC side terminals and PV cables more often

The DC side of the 4mm or 6mm PV dedicated cable 4mm specification is more widely used to fully meet the input requirements of component current. However, from the actual feedback of many cases, it is common for DC terminals to be burned off. Generally, it is mainly caused by loose wire pressing during installation. If the DC side terminal is found to be damaged during daily inspection, the terminal of uniform specification and model should be replaced in time, and the metal core of the terminal should be pressed tightly and the length should be ≥ 40 mm, and the positive and negative polarity should be paid attention to when connecting.

Check whether the grounding is in good condition

According to the relevant technical specifications of photovoltaic power stations, the grounding resistance value of lightning protection grounding is generally between 4 ~ 10 Ω; The grounding resistance of working grounding is generally less than 1 Ω. When the total capacity of low voltage power equipment does not exceed 100kVA, the grounding resistance is not allowed to exceed 10 Ω. The main purpose is to lead the surge current into the earth quickly when lightning occurs, and to protect the equipment and personnel from lightning damage to the greatest extent. Grounding wire is generally made of metal hot dip galvanized steel, which should be done well in the construction stage of power station. The common connection subways are flat steel sheets/strips with general specifications of 40mm (width) * 4mm (thickness), and their length should be more than 2.5 m. Buried in the ground at a depth of more than 1m from the ground to achieve good admittance effect. If grounding is not done well, it will not only have potential safety hazards, but also often have grounding fault codes, which will cause the system to stop working.

Components cleaning

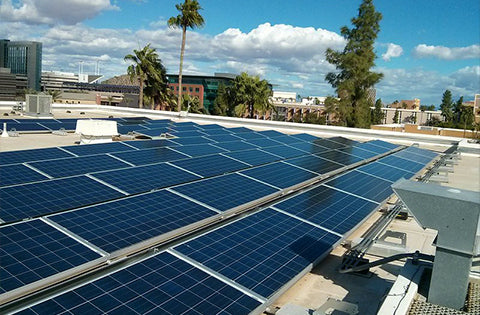

Module is always the source of income of photovoltaic power station. There are many impurities in the atmosphere that will be pressed to the ground or the surface of objects when encountering rain and snow. Module is exposed in the air in winter. After frequent rain and snow, module is covered, its output capacity is greatly reduced. If the module can be cleaned frequently, even if the irradiation is reduced, the output can be maximized within the limited intensity

Pay attention to these points when removing snow or dust from components:

1: Do not step on the assembly directly. Special tools for cleaning can be used with various components.

2: Flush the assembly with hot water. You can choose a water gun with a large impulse with normal temperature water.

3: Do not shovel snow or ice with hard metal tools such as shovels. Rubber tools can be used to protect the surface of the assembly.

4: If the snow on the surface of the component should be cleaned in time, don't wait for the snow to be cleaned for a long time. The snow melts and refreezes, which increases the cleaning difficulty and increases the damage probability of the component.

5: If the snow on the assembly is very thick, the floating snow should be removed with a soft broom first, and then the glass surface should be completely cleaned with tools such as cloth tows.

Focusing on the above points so that your photovoltaic power station can stabilize the income. Know more safety problems, following with SOLARPARTS.

Twitter: Solarparts Instagram: Solarparts

Tumblr: Solarparts Pinterest: Solarparts

Facebook: Shenzhen Solarparts Inc

Email address: Philip@isolarparts.com

Homepage: www.isolarparts.com