https://www.pv-magazine-india.com/2022/11/07/new-anode-material-could-enable-ev-battery-charging-within-10-minutes/

New anode material could enable EV battery charging within 10 minutes

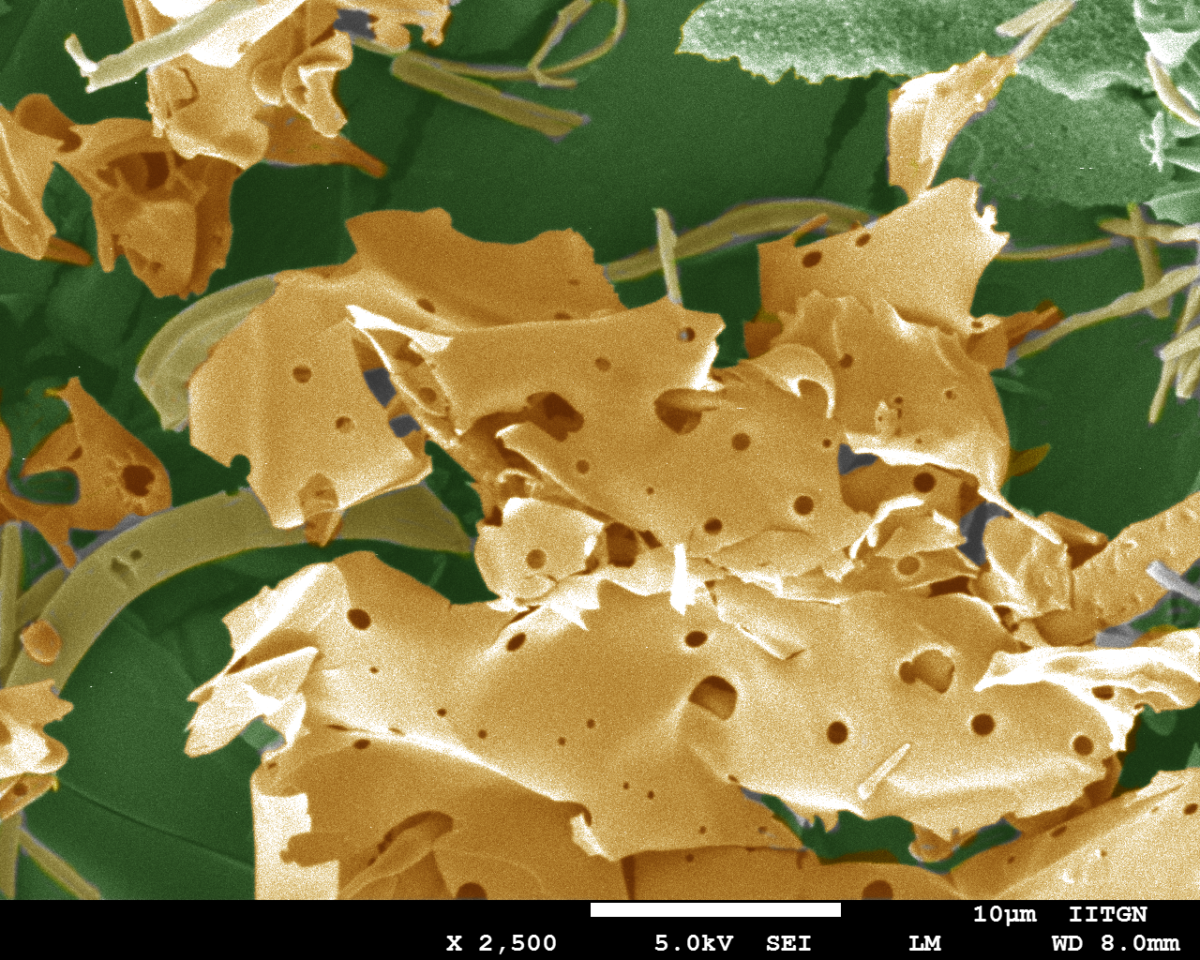

An electron microscopic image of the nanosheets that the researchers used to prepare the anode. The image is at a magnification of 2,500 times the original size. These nanosheets resemble autumn leaves at the nanoscale level. The large number of pores/pinholes in these nanostructures is what enabled an ultra-fast charging due to easy diffusion of Li ions.

Image: Indian Institute of Technology Gandhinagar

Researchers from the Indian Institute of Technology Gandhinagar (IITGN), in collaboration with the Japan Advanced Institute of Science and Technology (JAIST), has developed a new anode material that enables lithium-ion batteries (LIBs) to be recharged within minutes.

They developed the two-dimensional (2D) anode material using nanosheets derived from titanium diboride (TiB2), a material that resembles a multi-stacked sandwich, where metal atoms are present in-between layers of boron.

Currently, graphite and lithium titanate are among the most widely used anode materials in the commercially available lithium-ion batteries (LIBs) that power laptops, mobile phones, and electric vehicles. LIBs with graphite anode, which is extremely energy dense, can power an electric vehicle for hundreds of kilometers in one charge cycle. However, these are prone to fire hazards. Lithium titanate anodes are safer and also facilitate fast charging. But, they have a lower energy density, which means that they would need more frequent recharging.

The research team led by IITGN’s prof Kabeer Jasuja and JAIST’s prof Noriyoshi Matsumi found that when TiB2-based hierarchical nanosheets (THNS) were used to prepare the anode, a discharge capacity of 174 mA h/g (a unit that measures the energy capacity of a battery) can be obtained within 10 minutes at a current rate of 1 A/g. The intertwined carpet-like structure facilitates an efficient migration of charges in and out of nanosheets with ease, which resolves a Lithium-Ion diffusion-related challenge.

The researchers also found that this anode had an ultra-fast charging capacity with a considerable discharge capacity at high-capacity retention (up to 80% even after 10,000 cycles of operation), which means that batteries made with this material would give almost the same high performance even after more than 10,000 cycles of charging.

Moreover, there was no degradation or corrosion of THNS due to redox reactions and the porosity was also retained very well. This demonstrates structural stability with very less volumetric expansion (less than 40%) over thousands of charge−discharge cycles.

Explaining the high efficiency of the newly innovated battery material, Akash Varma, an MTech student, who is also the first author of this work, said, “It is the presence of titanium and boron atoms arranged in a carpet-like interweaved porous structure within the nanosheets that are helping in an efficient charge transport and storage.” Varma spent one year at IITGN and another year at JAIST as a part of his double master’s degree – a unique collaborative program between JAIST and IITGN.

The team stated that the pores within TiB2-based hierarchical nanosheets act as channels for fast and reversible ion transport; hence, Lithium-Ions can be rapidly inserted and extracted from the nanosheets resulting in faster-charging capacity.

The researchers emphasized that this is a promising technology for commercial applications where high energy density, high power, long life, and ultra-fast charging are desired. The research team plans to translate this work from the lab to a real-life application.

Prof Kabeer Jasuja, Dr Dinesh O Shah Chair Associate Professor of Chemical Engineering, IITGN, said, “What makes this work especially useful is the fact that the method to synthesize TiB2 nanosheets is inherently scalable. It only requires mixing the TiB2 particles in an aqueous solution of dilute hydrogen peroxide and allowing it to recrystallize. For any nanomaterial to translate into a tangible technology, scalability is the limiting factor. Our method to synthesize these TiB2 nanosheets only requires stirring and no sophisticated equipment, making it highly adoptable.”

Prof Noriyoshi Matsumi, Professor of Materials Chemistry, JAIST, said, “Nowadays, the requirement for high-rate charge-discharge technology is tremendously increasing to enable widespread commercialization of various kinds of electric vehicles in the future. Our findings can stimulate related research fields to invite more researchers to work on the application of unique 2D materials. We hope continuous research will contribute to the convenience of EV users, lesser air pollution on the road, especially in cities, and less stressful mobile life, which will enhance the productivity of society.”

This collaborative study was recently published in the “ACS Applied Nanomaterials”, an international high-impact journal: https://pubs.acs.org/doi/full/10.1021/acsanm.2c03054

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.