https://www.pv-magazine-australia.com/2022/05/30/novel-tech-for-extracting-hydrogen-gas-from-liquid-carriers/

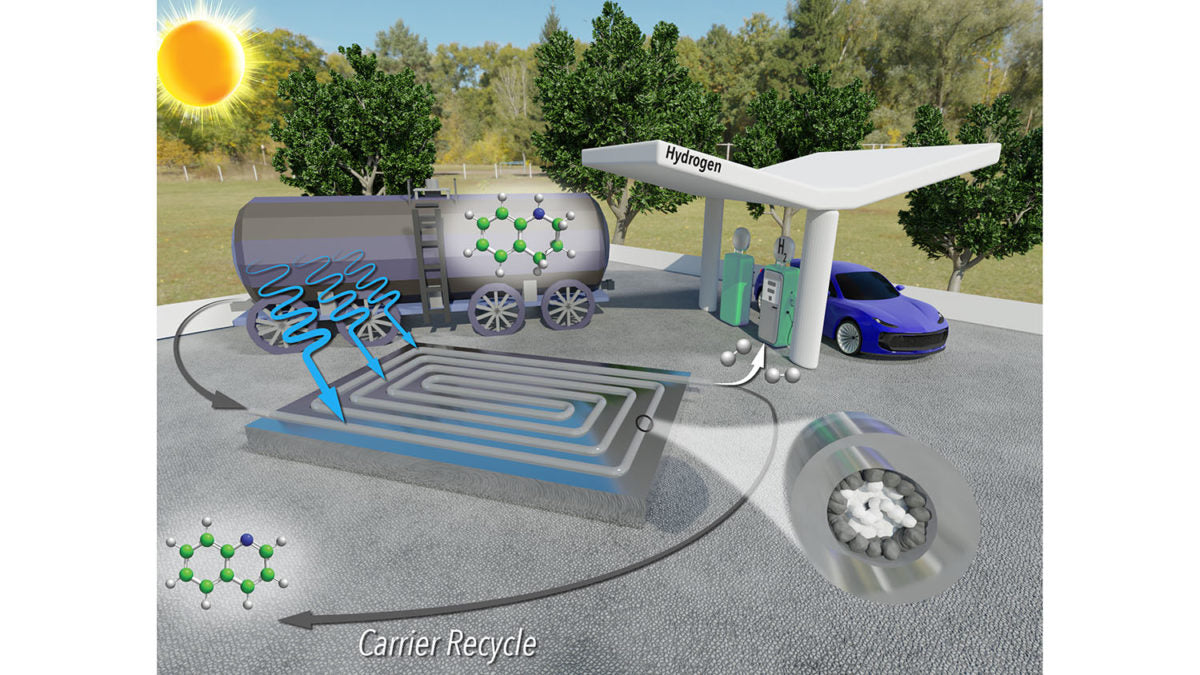

A scheme of the prototype reactor.

Image: North Carolina State University

From pv magazine Global | via the Hydrogen Stream

North Carolina State University (NCSU) has developed a continuous-flow reactor applying reusable photocatalyst and sunlight to extract hydrogen gas from its liquid organic carrier (LOHC) using less rhodium (Rh). The researchers achieved a 99% yield in three hours, reportedly eight times faster than conventional batch reactors. The room-temperature reactor resembles a thin, clear tube packed with micron-scale grains of titanium oxide (TiO2). The hydrogen-carrying liquid is pumped into one end of the tube. Only the outer grains of titanium oxide, the ones exposed to the sun at the other end of the tube, are coated with rhodium. These photoreactive catalysts react with the liquid carrier to release hydrogen molecules as a gas. “In a conventional batch reactor, 99% of the photocatalyst is titanium oxide, and 1% is rhodium. In our continuous flow reactor, we only need to use 0.025% rhodium, which makes a big difference in the final cost. A single gram of rhodium costs more than US$500,” said Milad Abolhasani, corresponding author of the paper recently published in ChemSusChem. According to the researchers, the system should be easy to scale up or scale out to allow for catalyst reuse on a commercial scale. “You can simply make the tube longer or merge multiple tubes running in parallel.” The flow system can run continuously for up to 72 hours before losing efficiency. The catalyst can be “regenerated” without removing it from the reactor in about six hours. The system can then be restarted and run at full efficiency.

Airbus launched its Zero Emission Development Centre (ZEDC) in Bristol, the United Kingdom, to develop, test, and manufacture cryogenic fuel systems. The centre will work on the full product capabilities from components up to the whole system and cryogenic testing. The new ZEDC joins other centres focused on cryogenic liquid hydrogen tanks in Spain, Germany, and France. “All Airbus ZEDCs are expected to be fully operational and ready for ground testing with the first fully functional cryogenic hydrogen tank during 2023, and with flight testing starting in 2026,” the European aerospace corporation wrote.

Toshiba Energy Systems and Solutions reached an agreement with Ireland-based Fusion Fuel to study collaboration opportunities, aimed at expanding sales of electrolysers in Europe and Australia. Fusion Fuel will evaluate the use of Toshiba ESS membrane electrode assemblies (MEAs) in its proprietary Proton-Exchange Membrane (PEM) eletrolysers; and Toshiba ESS will explore using its local sales channels to expand sales of Fusion Fuel’s PEM electrolysers in Australia. “Furthermore, the two companies will also explore potential collaboration for future sales of Toshiba ESS solid oxide electrolysis cells, which Toshiba ESS targets bringing to market in 2025,” Toshiba ESS wrote.

Chile development agency Corfo signed agreements with regasification plant GNL Quintero, iron producer CAP, and industrial gas supplier Air Liquide to finance the development of the first green hydrogen production plants on an industrial scale in Chile. The GNL Quintero’s 10 MW project aims to develop, construct, and operate a green hydrogen plant in the Valparaíso Region. CAP’s 12 MW project focuses on the Biobío Region, while the Antofagasta Region will host Air Liquide’s 80 MW project. The three companies were awarded US$5.7 million (€5.3 million), US$3.6 million, and US$11.7 million, respectively. “These three initiatives are part of the six selected by Corfo last December, which, once installed, will have a total electrolysis capacity of 388 MW, equivalent in size to what is currently in operation worldwide. They are expected to generate investments of US$1,000 million and produce more than 45,000 tons of hydrogen per year,” Corfo wrote.

The German Parliament passed the bill tabled by the Government to bypass specific procedural steps, like the need for an environmental impact assessment, to install two floating terminals in Wilhelmshaven and Brunsbüttel by the coming winter. The LNG facilities should be “hydrogen-ready.”

US-based Air Products, Oman’s energy group OQ, and Riyadh-based developer ACWA Power signed a joint development agreement toward a multibillion-dollar investment in a world-scale green hydrogen-based ammonia production facility powered by renewable energy in Oman.

Air Liquide invested US$250 million to open its largest liquid hydrogen production and logistics infrastructure facility in North Las Vegas, Nevada. The facility will produce 30 tons of liquid hydrogen per day, mainly for the mobility sector in California, wrote the Paris-based industrial gas business.

French green hydrogen producer Lhyfe and the Swedish local energy company Trelleborgs Energi teamed up for a pre-study for a local renewable hydrogen production system in southernmost Sweden. The results are due to be presented in the summer of 2022. Earlier this week, Lhyfe entered into an industrial agreement with Spain’s EDP Renewables to identify, develop, build, and manage renewable hydrogen projects.

Algeria’s Sonatrach and Italy’s Eni signed a Memorandum of Understanding (MoU) to accelerate the development of gas fields in Algeria and decarbonisation via green hydrogen.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

<