https://www.pv-magazine.com/2023/01/13/brek-unveils-400-kw-silicon-carbide-string-inverter/

Brek unveils 400 kW silicon carbide string inverter

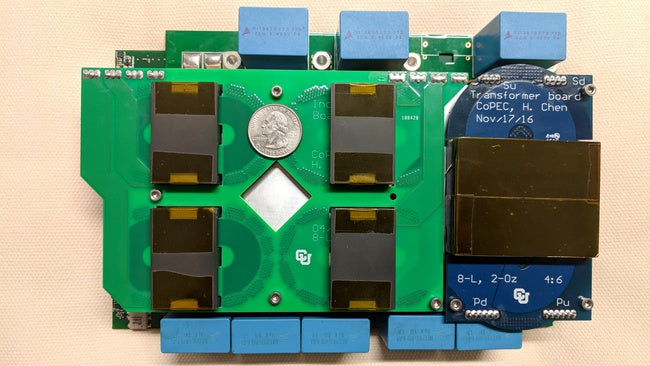

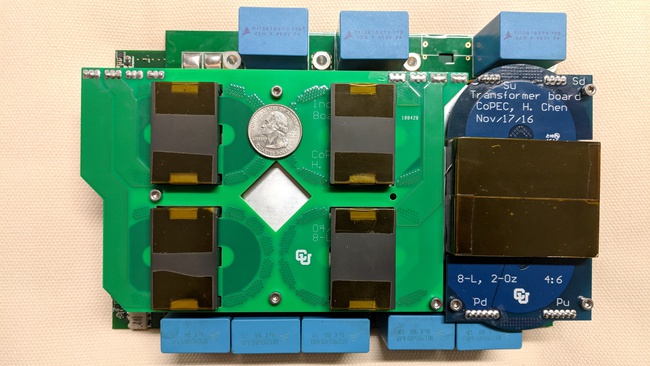

Brek's 250 kW SiC solar inverter

Image: Brek Electronics

Brek Electronics has developed two string inverters with its novel composite architecture, optimized for silicon carbide (SiC) components.

“The design replaces film capacitors with machine-placeable ceramic capacitors and uses planar magnetics,” a company spokesperson told pv magazine.

The US manufacturer said the SiC metal oxide semiconductor field effect transistors (MOSFETs) have 20 times faster switching frequency than silicon insulated-gate bipolar transistors (IGBTs). The two devices have power outputs of 200 kW and 400 kW. The SiC components provide the 400 kW inverter with a power density of 4 kW/kg, according to the company.

The Brek IS400 measures 762 mm x 381 mm x 635 mm. Brek estimates its weight at 100 kg, but it notes that some parts are still missing from the calculation. The device has an efficiency of up to 99%. It has a DC power voltage from 875 V to 1,500 V and an ambient operating temperature ranging from -40 C to 60 C.

Popular content

The IS200 device has the same efficiency and operating temperature, but measures 381 mm x 381 mm x 635 mm and weighs around 50 kg. It has one maximum power point tracking (MPPT) input, while the IS400 has two. The maximum input current DC per MPPT is 222 A.

Berk claims the IS400 has a lifetime of around 15 years, with lab tests reportedly showing an improvement in the meantime to failure compared to conventional silicon. It said it will submit the inverter for UL testing in the fourth quarter of 2023. It expects to release it in the first half of 2024.

Its silicon carbide-based composite architecture technology for string inverters was one of the finalists in the US National Renewable Energy Laboratory’s (NREL) American-Made Solar Prize. Silicon carbide-based inverters are known for having higher power density and lower overall system costs than traditional inverters. However, defects at the interface between the silicon carbide and the insulating silicon dioxide material are still issues for such devices.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.