https://www.pv-magazine.com/2023/04/20/new-selenization-process-paves-way-for-14-efficient-kesterite-solar-cells/

New selenization process paves way for 14%-efficient kesterite solar cells

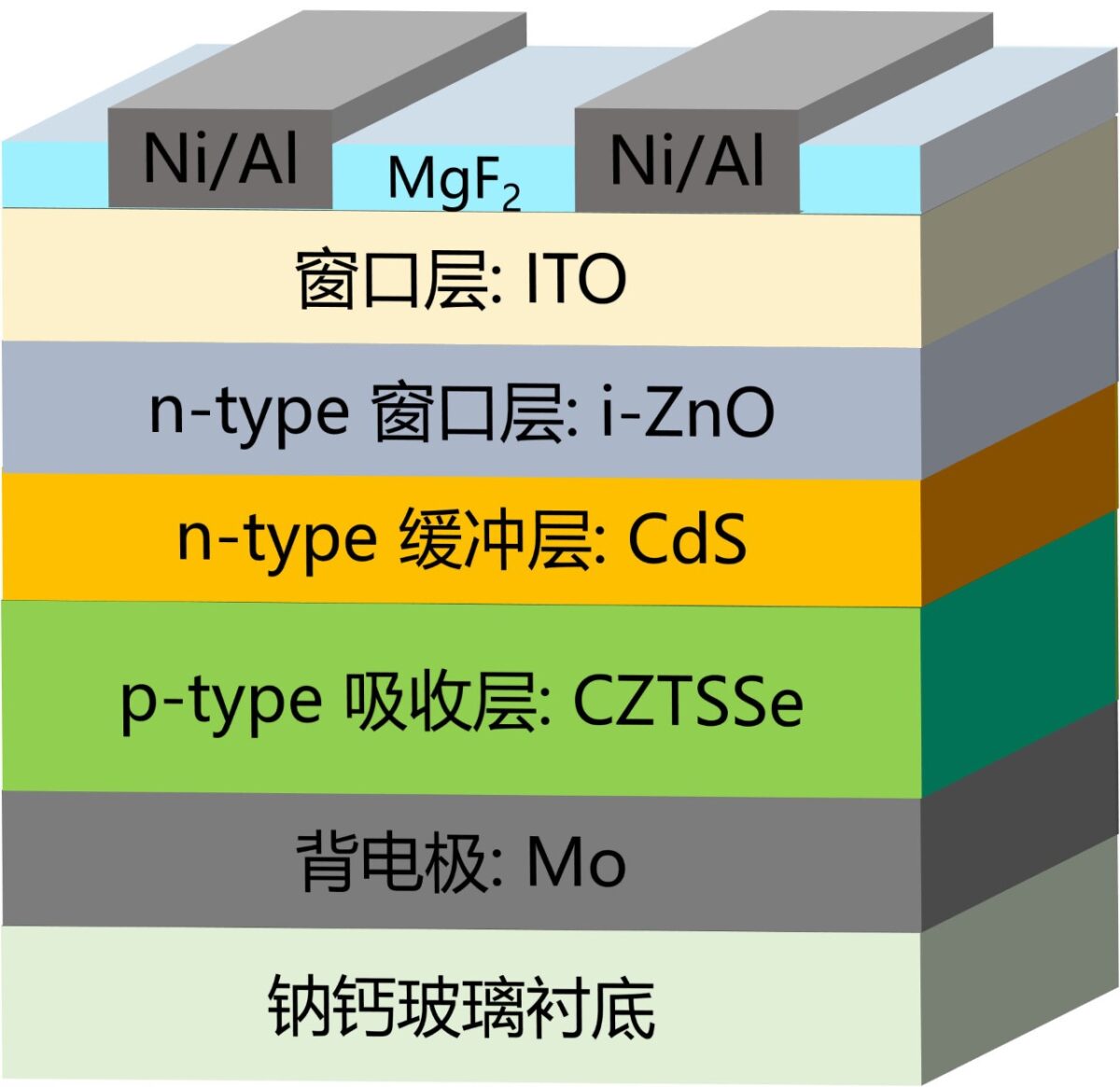

Schematic of the solar cell

Image: Nanjing University of Posts and Telecommunications

Researchers at the Nanjing University of Posts and Telecommunications in China have designed a kesterite (CZTSSe) solar cell through a new selenization approach that reportedly ensures the high-crystalline quality of CZTSSe absorbers, with low defects.

“Considering the advantages of low cost, high material stability, tunable bandgap, and high industrial compatibility of CZTSSe solar cells, we believe this solar cell has a promising commercialization prospect, such as BIPV and other suitable applications,” researcher Dongmei Li told pv magazine.

The scientists explained that selenization annealing is a key process in the development of highly efficient kesterite solar cells. In this step, tin(II)sulfide (SnS) is generally added but an excessive presence may result in defects in the CZTSSe absorber.

They also claim to have regulated the kinetic process of phase evolution by tailoring a positive chamber pressure to reduce selenium (Se) partial pressure.

“The collision probability between the precursor and gaseous Se molecule can be decreased at the heating-up stage (200 C to 400 C) of the selenization reaction,” they explained, noting that this has contributed to the reduction of bulk defects by around one order of magnitude.

The research team built a kesterite cell with an interfacial layer made of molybdenum (Mo), the kesterite absorber, a cadmium sulfide (CdS) buffer layer, a window layer of zinc oxide (ZnO), and an indium tin oxide (ITO) substrate. They finalized the manufacturing process via the thermal evaporation of nickel (Ni) and aluminum (Al) top electrodes and an antireflective coating based on magnesium fluoride (MgF2).

Popular content

The device has a power conversion efficiency of 14.13%, an open-circuit voltage of 551.20 mV, a short-circuit current of 35.74 mA cm−2, and a fill factor of 71.73%. They also internally certified the cell efficiency at 13.8%.

“The highly efficient kesterite solar cell also shows excellent long-term stability in ambient environment without encapsulation,” the academics stated.

The group introduced the cell technology in “Control of the phase evolution of kesterite by tuning of the selenium partial pressure for solar cells with 13.8% certified efficiency,” which was recently published in Nature Energy.

“This work provides a kinetic regulation strategy for further understanding and regulating the phase-evolution process of kesterite, especially optimizing the phase-evolution path to achieve highly efficient kesterite solar cells,” the scientists said.

Kesterite is one of the most promising light absorber material candidates for potential use in lower-cost thin-film solar cells.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.