https://www.pv-magazine-australia.com/2023/04/11/battery-hydrogen-vs-battery-flywheel/

Battery hydrogen vs. battery flywheel

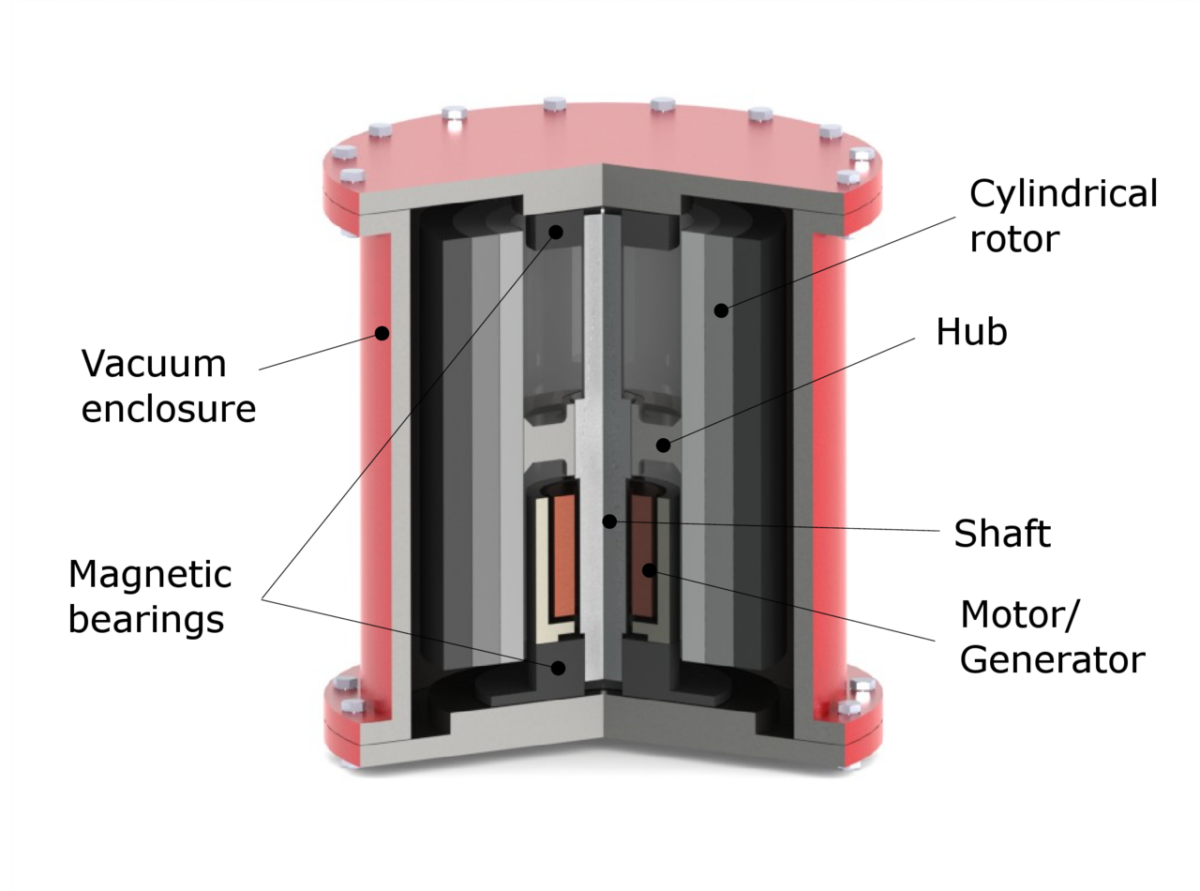

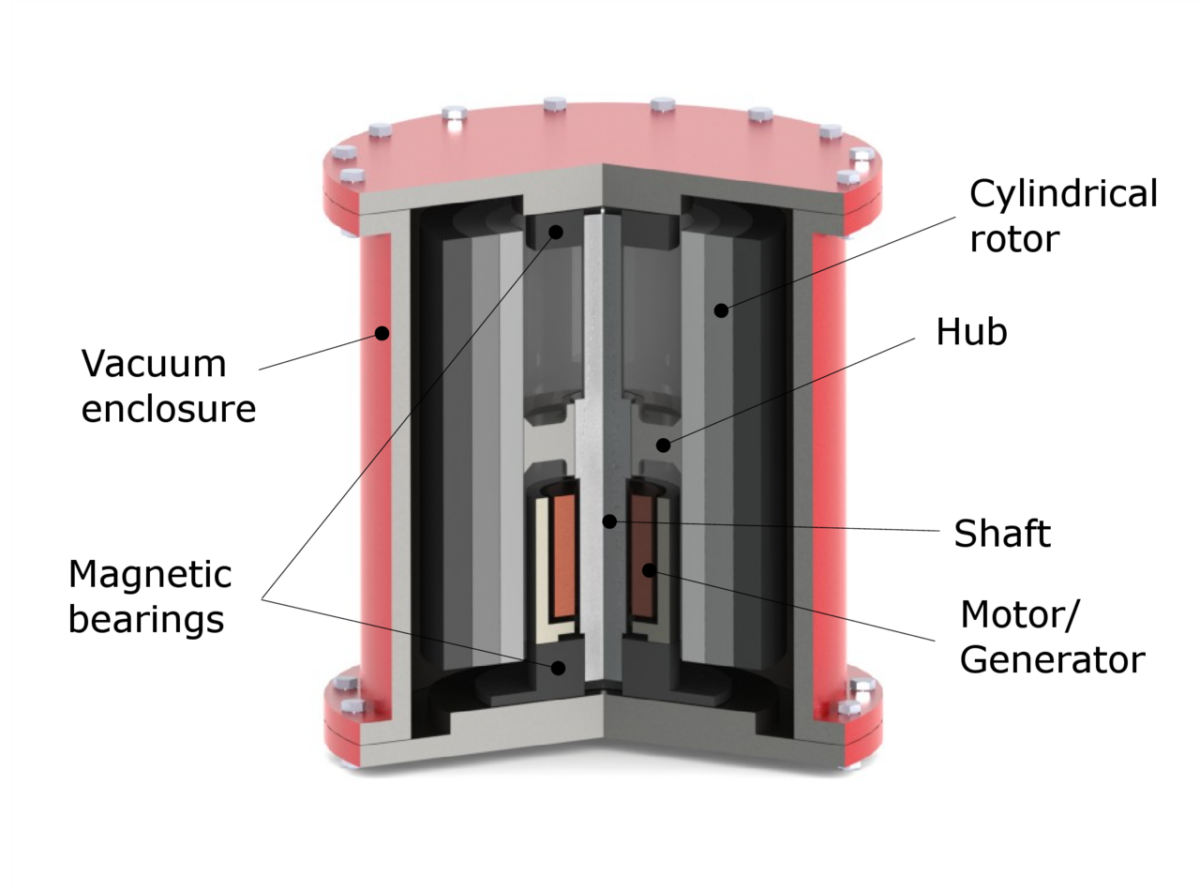

Main components of a typical flywheel

Image: Pjrensburg, Wikimedia Commons

From pv magazine Global

Researchers from the University of Perugia in Italy have compared two different combinations of energy storage systems connected to photovoltaics: one based on reversible solid oxide cells (rSOC) and batteries, and one that relies on flywheel storage and batteries.

“Our analysis considered annual photovoltaic generation and electric load actual dataset,” researcher Linda Barelli told pv magazine. “We included a statistical analysis to obtain the most representative days, dynamic modelling of the storage systems, simulations to define components sizing and to extrapolate the evolution of annual battery state-of-charge, battery lifespan assessment through application of the rainflow cycle counting algorithm, and a detailed economic evaluation of the levelised cost of energy (LCOE) and the levelised cost of storage (LCOS) including subsidies for self-consumption.”

The Italian group presented its findings in “Battery-hydrogen vs. flywheel-battery hybrid storage systems for renewable energy integration in mini-grid: A techno-economic comparison,” which was recently published in the Journal of Energy Storage The researchers said that the two storage system configurations are designed for applications in minigrids equipped with PV plants.

Their modelling was based on a minigrid with a 245 kW PV system connected to a common AC bus through an inverter, with the connection to the medium-voltage grid carried out through a transformer. They considered the following main parameters: the daily mean power, the daily power bandwidth, the ratio between the daily bandwidth and the mean power, and the the daily mean power ramp.

For the flywheel-battery scheme, the scientists considered a low–speed mechanical flywheel made of steel with ceramic bearings and an operating speed range is 3,500 rpm to 8,500 rpm. For the rSOC-battery configuration, they assumed a rSOC stack that can can achieve round trip efficiencies between 38% and 48%. For the battery–flywheel system, the battery had a size of 260 kWh and the flywheel had a capacity of 180 kW. For the rSOC-battery architecture, the battery had a capacity of 450 kWh and the rSOC featured a power of up to 80 kW.

The scientists assumed a cost of €970 ($1,586)/kW for the PV system and a cost of €411/kWh for the batteries. For the rSOC system and the flywheel technology, they considered initial costs of 2,930/kW and €162/kW.

“It is noteworthy to mention that, due to the current energy crisis, such an index has quickly risen from the last months of 2021,” the researcher said. “Therefore, LCOE estimation based on the short–term electricity price instability might lead to a fleeting outcome.”

The research group found that the system based on rSOC and batteries has an LCOE of €0.22480/kWh while that based on flywheel and batteries achieved an LCOE of €0.18/kWh.

“None of the systems proposed attains the market parity, and the results are rather far from the 2020 IRENA target for PV systems,” the said.

The rSOC+battery combination may potential reach grid parity when the market price is higher than €0.380/kWh and the flywheel-battery scheme may become competitive when market price exceeds €0.320/kWh.

“As main outcomes for this integrated methodology, it appears that self-consumption rewards let the flywheel/Li-ion battery storage system reach a LCOS agreeing with 2021 average market parity,” Barelli said. “I see good applications for this configuration in power smoothing and hybrid storage systems, in order to process the most fluctuating profiles by reducing the stress on other systems which can thus be dedicated to meet storage demand over longer timeframes, resulting in greater system efficiencies and durability.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

<