https://www.pv-magazine-australia.com/2022/12/10/weekend-read-automate-foldout-for-a-ultra-low-cost-solar-future/

Weekend read: Automate, foldout for a ultra-low-cost solar future

At this project in Chile’s Atacama Desert, 5B demonstrated its system enables a team of fewer than 10 workers to install more than 1 MW of PV in a day.

Image: 5B

From pv magazine ISSUE 12 – 2022

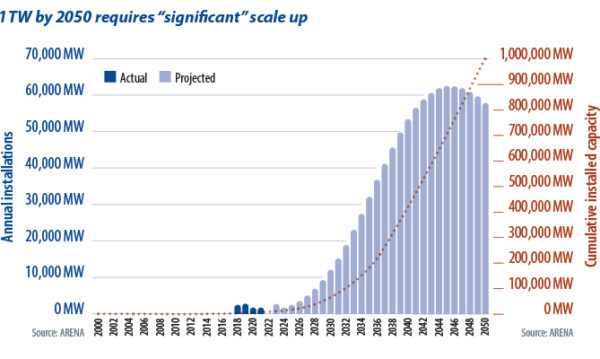

Ultra-low-cost solar (ULCS) has definitively entered the everyday lexicon of energy terms since Darren Miller made it the topic of plenary session conversation at the All-Energy conference in Melbourne in October. Miller is the chief executive of the Australian Renewable Energy Agency (ARENA) and ULCS has become the organisation’s new push – not just for the contribution it will make to bringing commercial green hydrogen to reality, but as a major disruptor of how the world currently uses energy.

In his plenary address, Miller said that Australia’s role in global decarbonisation will be to “capitalise on our unfair advantage in renewable energy generation … If we can make ULCS a reality, we can dramatically and cost-effectively reduce emissions in hard-to-abate sectors.“ And, he added, “we can maintain our position as a major producer and exporter of energy products.”

Once a pillar of the previous Australian Liberal Coalition government’s “stretch target” to achieve green hydrogen at a cost of $2 (USD 1.35) per kilogram, ULCS has eclipsed the hydrogen bandwagon it was hitched to – a realignment of horse and cart for which we have global conditions to thank.

In just a couple of revolutions of the planet around the sun, world economics have been shaken to the core by the Covid-19 pandemic, war in Ukraine, and other schisms in the diplomacy-as-usual ecosystem of international relations. National energy security and manufacturing capability have come to the fore in an environment where every country has designs on decarbonisation, and not even China will be able keep up with demand for solar panels at the terawatt levels anticipated.

Miller suggests that the success of solar energy in becoming recognised by the International Energy Agency as the lowest-cost source of energy in history had lulled people into looking for the next big thing to drive down emissions. He says he has “heard from very senior people in the industry, ‘OK, job done on solar, what’s next?'” But he admits he might have agreed with them, until recently.

ARENA and solar

“I’ve realised that thinking is fundamentally wrong,” he adds. “In fact, we need to go further in doing more with solar.” Building on proven technology that is known to be scalable is the most rational path to decarbonising economies. Hence, ARENA is strategically focusing on projects that can achieve solar generation at $0.30 per watt, including a 30% cell efficiency target, by 2030.

In June 2021, ARENA beefed up its funding by $45 million to the Australian Centre for Advanced Photovoltaics (ACAP), which coordinates the collaboration of several national research institutes and is based at the University of New South Wales (UNSW). ACAP Director Renate Egan says the funding – which is focused on developing better, cheaper, more sustainable solar technologies – has allowed breakthrough research to continue in a refreshed context. One example has been R&D into tandem solar cell structures which enable the absorbtion of more light. Research work such as those advances is now focused on the government’s “Solar 30 30 30” target – 30%-efficient modules for AUD 0.30/W at utility scale by 2030 – and will include seeding and testing of new approaches.

Cell efficiency is definitely not the only fruit of the 30 30 30 scenario, but Miller articulates what many have concluded: “If something is more efficient, you can generate the same output with less material, or more output with the same material.” In this case, “material” covers all inputs, from silver to connective cabling, to aluminium for module framing, to steel for the racking of solar farms, to land. Increasing solar panel efficiency “is a good idea,” says Miller, to enable savings on these elements, many of which will become more constrained – think silver and land – thus driving up the cost of solar unless the industry changes its approach.

Deployment cost reduction

The richest potential savings are on the “balance of systems” side. Solar panels were once the most expensive component of large-scale solar projects; they now make up less than one-quarter of the cost of building out a solar farm. Miller says that if he could wish for one thing to enable ULCS, it would be “for the world’s best innovators to jump on board with their ideas around how to automate and industrialise the actual construction of solar farms.”

He names Australian innovator 5B, with its prefabricated, foldout Maverick array technology, as the standout in this field, saying, “it’s very much the lone purveyor of changing how we do things.” ARENA announced $14 million of funding to 5B in 2021 – to advance plans to automate factory production of its turnkey arrays, which incorporate up to 90 modules each.

The company was founded in 2009 with the intention of reducing the cost of renewable energy and accelerating its deployment. The startup launched its first deployable arrays in 2017, when it had a production capacity of 100 kW. “We were hand building in a small shed,” says 5B co-founder and Chief Executive Chris McGrath – and the cost of production and deployment (not including the solar panels), was between $0.60/W and $0.70/W.

Today, with an annual production capacity of around 100 MW, that cost is $0.20/W to $0.25/W. Within a couple of fiscal years, further evolution of the technology, value engineering to optimise material use, increased automation, and a leap in production capacity to around a gigawatt will bring down the cost per watt to less than $0.10, according to 5B’s McGrath.

The company’s industrialisation agenda includes not only factory automation, but also automated packing of the arrays for shipping, unpacking them, deployment, and maintenance of the arrays over time. Displacing the number of tradespeople needed on site may not be a popular idea but the truth is that projects such as the 17 GW to 20 GW Sun Cable project in Australia’s Northern Territory, to which 5B is the preferred technology provider, will not be possible without machinery. Never mind that skilled workers and labourers are in short supply. Streamlining and automating deployment, says McGrath, is what will really push the fast forward button on ULCS.

Foldout future?

5B can currently deploy more than a megawatt of solar per day with a team of fewer than 10 staff – a world beating feat it achieved in May last year at a 10 MW project in Chile’s Atacama Desert being developed by AES. Next year, McGrath anticipates the new Maverick technology currently being tested will enable deployment “10 to 20 times faster on a per person, per day basis.”

And then there’s land. Economical use of land is as important in Australia as it is in Europe. The country may have a vast interior but accessible land is still scarce, says Miller. Sites may have cultural significance, ecological value, or opportunities for other sectors, and “we must treat it as a scarce commodity,” he explains.

A system such as 5B’s Maverick – ground-mounted, with no corridors required between east-west-facing arrays angled at 10 degrees to the ground – “packs the land much fuller with actual modules,“ says Miller. “Because you don’t have to worry about overshadowing like you do with single-axis tracking.“ 5B claims to produce up to two times the energy of conventional mounting systems on the same land area.

Future challenges

Delivery of ULCS doesn’t stop at achieving economies of scale. McGrath says that at 5B, “assembly and deployment of our technology are at the point where both processes can only just keep up with each other, which shifts the challenge to how to make sure we effectively integrate upstream, so that we can hoover up enough solar modules” to make accelerated rollout of PV at gigawatt and then terawatt scale a reality. And even once you have DC cabling, inverter installation, and AC cabling in step with such a paradigm shift, “can development and financing keep up with that pace of deployment?” asks McGrath.

ACAP’s Egan believes the reduced risk conferred by achieving the $0.30/W system cost ties performance and yield modelling into a package that renders decision making smoother. “People will more easily project how much electricity they’ll generate and enter agreements on delivery and supply – the better those numbers are, the lower the risk and therefore the better the finance conditions,” she says, noting that this will further reduce the cost of solar.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

<

![[Dans les allées d’Energaïa] PowR Group veut révolutionner le solaire en façade](http://isolarparts.com/cdn/shop/articles/powr-scaled.jpg?v=1670775980&width=1440)