https://www.pv-magazine-australia.com/2022/04/30/weekend-read-back-to-the-future-with-bess/

Weekend read: Back to the future with BESS

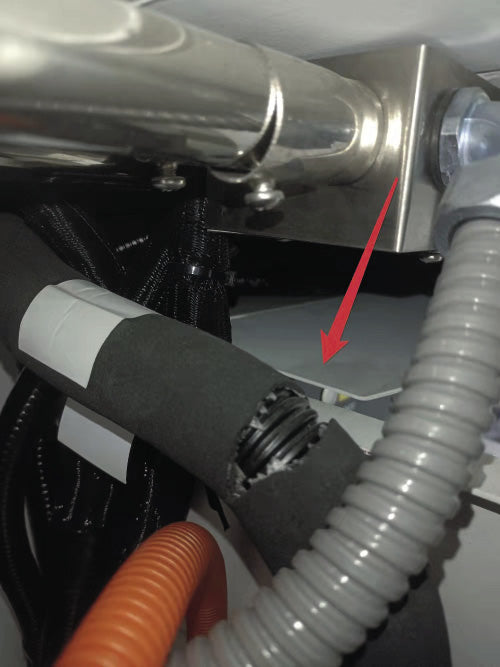

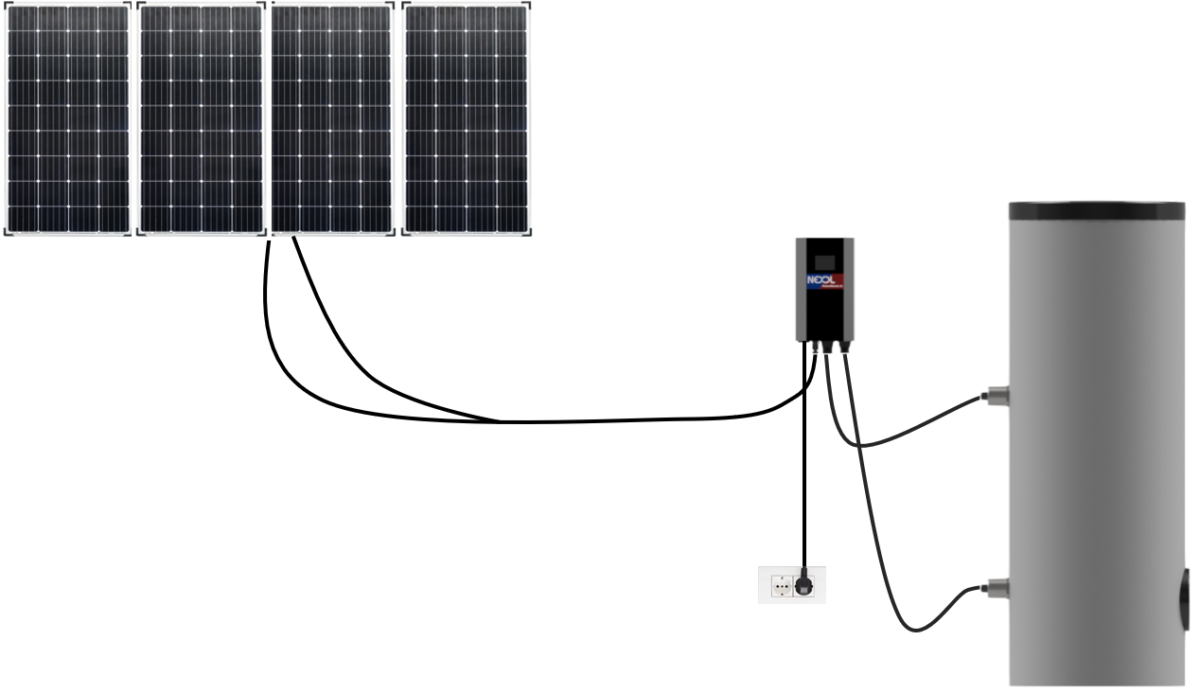

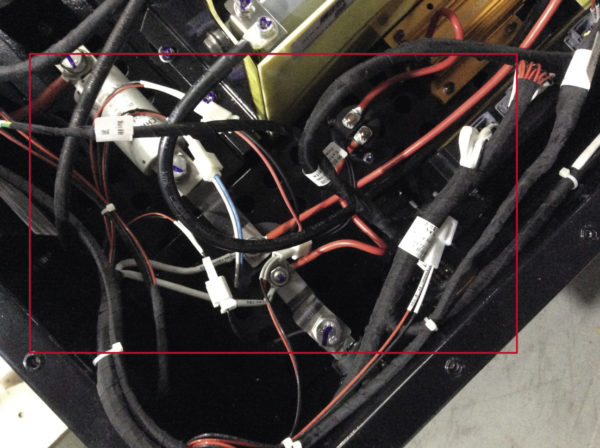

Representative faults witnessed during BESS Factory Acceptance Tests, including (from top to bottom) an example of a broken thermal insulation tube; water leakage, indicative of failed waterproof testing; messy wiring configuration; and leakage in a cooling system.

STS

From pv magazine 04/2022

An STS client and PV industry veteran recently remarked: “It feels like I am back in the PV industry of 2010,” after having been put in charge of the procurement of battery energy storage systems (BESS) for a large European developer. For many in the industry, the level of maturity of the BESS market is comparable to that of the PV industry a decade ago.

The number of BESS players is ballooning, and many of them are shipping out of China. Many products exist essentially at the stage of prototypes, and manufacturing facilities are mushrooming as cash is injected into the promise of a market growth of 40% per year over the next decade, according to recent International Energy Association forecasts.

Like the PV industry a decade ago, there are severe challenges ahead of procurement managers in charge of sourcing reliable BESS systems to feed their ambitious pipelines. These relate to technology choices; supplier identification, qualification and selection; manufacturing ramp-up and maturity; supply chain traceability, transparency, resilience and logistics; and system safety.

The elephant in the room is the latter. We’ve all seen the news stories about recalls and system shutdowns due to thermal runaways, fires and even explosions. For that matter, the stakes of quality assurance are even higher than for PV modules.

Lessons from PV

Coincidentally, 2010 was also the year of incorporation of STS. Throughout the years, STS has witnessed the slow increase in the maturity of PV manufacturers, moving from two busbars on a 125mm wafer to 210mm-based half-cut PERC multi-busbar modules. Today we observe that most module manufacturers have acquired the capability of manufacturing high-quality products.

However, some have also acquired the knowledge of where cutting corners will shave off a fraction of a penny in manufacturing costs. The role of companies like STS in the PV industry today, is to position an inspector at every corner a manufacturer is likely to cut, ensuring the level of quality required for gigawatt-scale development and financing.

The role of STS in the BESS industry is different. It’s back to the core mission it was setup to achieve more than a decade ago: detecting quality issues and communicating them to both buyers and suppliers, thereby improving the overall quality delivered to the industry. To date, STS has performed conformity assessments of over 2GWh of BESS, including different cathode chemistries (LFP vs. NMC), different cell configurations (pouch vs. cylindrical), different system sizes (residential vs. utility-scale). The most common and representative non-conformities observed during our practice are summarized in the table to the top right.

STS observes that several of the most worrying risks are detected during Factory Acceptance Tests (FAT). Failures of the fire protection system, or failures of the grounding test are severe safety issues that have been observed on a regular basis.

It has also been observed that not every FAT scope is the same. Even a test as critical as the capacity test is not performed in the same way by different manufacturers. Comparing the proposed scope of FAT to the rule-of-art is therefore essential. In fact, we also recommend verifying the test procedures, pass/fail criteria, availability of the measurement tools and so on. STS has seen projects in a deadlock because the factory was not able to deploy FAT on time, leaving the system owner with the choice between incurring delays in shipment, usually delaying the entire project, or accepting systems to be delivered without final factory test.

| Most common nonconformities found by STS during almost 2GWh worth of BESS inspections | |||

| Most common nonconformities observed during quality assurance activities |

Potential risks | Risk-control recommendations | |

| Before Manufacturing |

|

|

|

| During Manufacturing |

|

|

|

| During Factory Acceptance Testing |

|

|

|

Pack assembly

Besides FAT witnessing, the second most critical step for quality assurance is probably the assembly of cells into packs. That is where the supply chain of stationary systems often forks away from the supply chain for mobile applications, where the quality requirements are today much higher. As seen in the table above, recommended quality assurance activities at this stage include a thorough audit of the pack assembly lines, incoming quality control of components, pre-shipment inspection, and container loading supervision.

Finally, with increasing constraints on logistics, and many customers to serve in parallel, STS observes that many projects struggle with on-time delivery of components. It is expected that this may be exacerbated further by supply issues as the market growth outpaces the supply. Even global supply of the essential lithium is projected to become a bottleneck in the next few years. A close monitoring of the project planning is therefore recommended, including supply chain (resilience is an important factor here), training plan, manufacturing ramp up, sourcing of key components and so on.

In short, if there is only one quality check that can be carried out on a BESS project, ensure that it is a presence on the factory floor during the entirety of the Factory Acceptance Test. Then, to further mitigate the residual quality risks, bring some attention to the pack assembly processes. Finally, to ensure on-time delivery, it’s recommended to closely monitor the logistics of the entire manufacturing

project.

About the author

Frédéric Dross received his Ph.D. in semiconductor device physics from Telecom ParisTech in France. Dross has been working in PV for more than 15 years, initially in cell and module R&D for imec in Belgium and Hanwha in California. He then served as the head of the module testing business at PVEL/DNV GL and as VP technologies Americas for DSM. Since June 2020, Dross has been working as VP of strategic development for STS, the global leader in PV module inspection.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

<