https://pv-magazine-usa.com/2022/05/31/cab-solar-more-than-cable-management/

CAB Solar: more than cable management

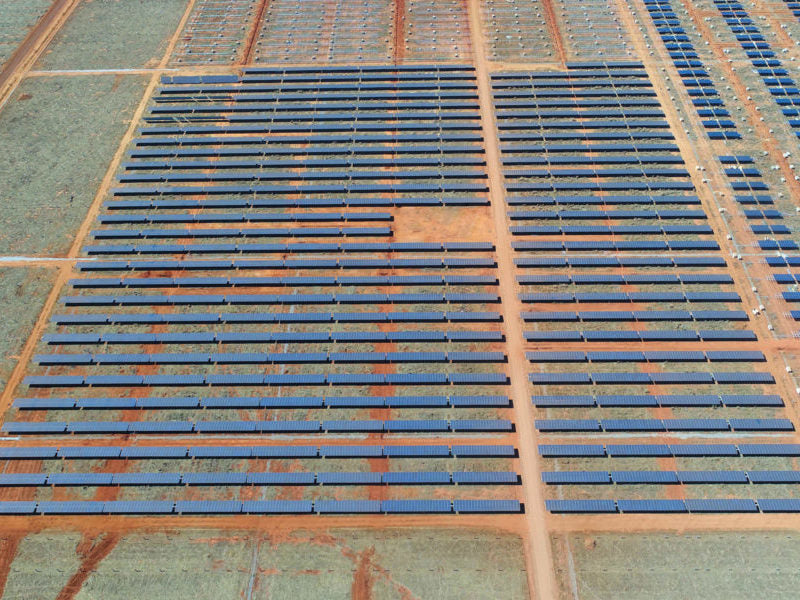

CAB Solar hangers used in a solar installation.

Image: CAB Solar

In the world of utility scale solar development, where the margins to make a multi-million-dollar asset as financially viable as possible are razor-thin, any innovation that reduces materials used, cuts labor costs, increases efficiency, or otherwise leads to increased yield is going to be pursued fervently. Cable management systems might never drum up the same excitement as new modules or trackers, but for the folks working at CAB Solar, the 2021 pv magazine Award winner in the BOS category, the name of the game is proficiency, not publicity.

When it comes to cost reduction, attention is understandably focused on the most visible and prominent aspects of an installation: large, high-powered modules with ever-increasing efficiencies, and the yield-increasing single-axis trackers that house those generating behemoths.

CAB is headquartered in Pennsylvania, split among two divisions. CAB solar operates out of a 105,000 square-foot facility in Johnstown, a short drive east from Pittsburgh, while non-solar CAB products are manufactured in a 134,000 square-foot facility in nearby Evansburg.

CAB Solar’s patented cabling system consists of PVC-coated steel cable hangers — to ensure that no potentially sharp edges come into contact with the cables — strung along a copper-clad messenger wire that acts as the electrical grounding conductor. In practice, the solution offers significant cost reductions in labor, materials and engineering, especially when compared to popular alternatives of trenching the cables or using cable trays.

“Using the messenger wires as the ground allows you to run one messenger wire, instead of having to run a messenger wire and then a separate ground,” explained Tim Wedding, solar program manager at CAB. “When there’s only one connection, it simplifies the installation, shortens the installation time, and decreases the amount of product being used. It’s a large cost saving in both product and labor.”

While the company has existed for almost 100 years, CAB didn’t get into the business of solar hangers until 2014. Founded in 1927, the company has had a hand in manufacturing a litany of products, from disposable food service kits, to pillowcases, to making mops and laundry bags for the US government. According to President and CEO, Tara Bosserman, CAB originally got into cable management in the 1970s, manufacturing hooks and hangers for use in the mining industry.

The company found success in the manufacture of this application-specific hardware, so much so that, in 2014, an unnamed solar company contacted CAB, asking if their products would work in a solar application. “When this opportunity came along with solar, we took what we already knew, which was hooks and hangers, and we just moved it into the solar industry,” said Bosserman. “We were already servicing above-ground cabling for electrical, and we had some of our products used in shipbuilding. And so we, you know, transitioned into the solar industry.”

As simple as Bosserman makes the process sound, the reality of the company’s transition was much more intensive, as Wedding was quick to outline. “It was a pretty big overhaul,” he said. “All of our designs for solar, probably 99.9% of them are new products that we’ve developed over time, working with customers identifying what they needed, working within national electrical code to make sure that they were complying, and then trying to develop our products that we could make easily that would fit within the window of the CAB system. The L brackets that hold the messenger wire in place were a new product for us, and the messenger wire itself wasn’t something that we had ever dealt with before… It took a considerable amount of time for us to identify what parts would work and what we needed to do to adjust the designs.”

While it’s not uncommon for one manufacturer to have a hand in a series of different industries, CAB has done it seemingly effortlessly and consistently throughout its 95-year history. This is because CAB’s focus has never solely been on the industries it operates in or the most profitable product to manufacture at the time, but to provide employment opportunities to individuals who would otherwise be limited in their options.

“We’ve always looked at how we can provide employment opportunities for individuals with disabilities,” explained Bosserman. “And we found that, as a nonprofit in the late 60s and early 70s, trying to rely on government funding and charitable contributions that many nonprofits rely on, that we wanted to take a different route. We really wanted to look at how we could sustain our organization, and that was through providing products to different sectors.”

Through a partnership with The Cambria County Association for the Blind and Handicapped, CAB has made it the company’s mission to provide quality jobs to people with blindness, as well as individuals living with other disabilities. Through employment and revenue generated from CAB’s cabling system and other products, the company is able to support more than 500 persons with disabilities.

“We’re a small community,” said Bosserman. “Early on, there was a need for a place for individuals with disabilities to come not only for employment opportunities, but for rehabilitation and vocational training, and socialization. We have a very dynamic social recreational program as well here. I think that as far as what has sustained us, when you’re working with our individuals, and you’re seeing them and you’re talking to them, as staff, we are driven to our mission of having them here and providing employment opportunities for them.”

Of the 343 workers at CAB Solar’s Johnstown facility, around 230 are individuals with disabilities. Bosserman went on to outline that this drive to provide the best employment opportunity possible for individuals with disabilities has gone so far as to dictate the company’s manufacturing process and what products it pursues. “When we find a product, we look at how it can blend in with all of our employees, and the diversity that they have with their disabilities,” she said. “I think that has really helped us to continue to push forward and push our organization to the next level.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.